Floor Coatings

Home »

Garage Floor Coatings

For garage floors, we use only the best formulations of polyurea floor coatings to make your floor beautiful and durable! When installing a residential garage floor in a variety of climates, there are many things that we need to consider when choosing the best products and systems:

- Warm or Cold Weather

- Concrete Expansion

- Road and household Chemicals

- UV Rays

- Physical Impacts

- Abrasion Resistance

Outdoor

Transform Your Plain Concrete to a Beautiful Showpiece

In addition to residential and commercial interior coatings, liquid floors also offers outdoor coating services. We are able to protect and enhance virtually any concrete surface with a fast, affordable coating. Products range from invisible fortifying agents to a glossy wet look and everything in between. You might consider transforming any of these areas around your home. The textured coating makes the surface anti-slip while being easy to maintain. With maximum strength and durability to calcium, our products are a logical choice to beautify your exterior.

Applications

- Patios

- Sidewalks

- Driveways

- Pool Decks

- Lanais

- Porches

- Walkways

- Entry Areas

- Sun Decks

- BBQ Area

- Florida Room

- Outdoor Kitchens

Residential

When it comes to residential floor coatings, we’ve got your floor covered! We offer a full range of products and systems to ensure you’re getting the best quality and value from your investment. Because of our experience and training, we understand the differences between the various products on the market. For that reason, we only use advanced polyurea formulas throughout our whole floor coating system. This includes a pure polyurea base coat combined with a polyaspartic polyurea top coat.

Our coatings for garage floor and concrete are available in a variety of solid colors, styles, granite, stains, or as clear sealer to give style to your concrete floor. Our products can also be used as a sealer on acid stained concrete, the polished or colored concrete and even stamped concrete. The most interesting part is that it only takes two days to be installed and be completely dry. 48 hours after installation, you can park your car on your new garage floor and enjoy.

Commercial

From warehouses to manufacturing facilities and kitchens to hospitals, we have the right coating to fit your need. Our extensive line of products and systems and preparation equipment will ensure minimal down time and a successful coating application every time. We discuss and inspect all projects up front and work with you from beginning to end to make sure you end up with the perfect coating to match the demands of your specific floor.

Easy Maintenance

Often in commercial establishments, maintenance cost can become very expensive. The financial investment for cleaning, waxing, and polishing must be considered when it comes time to evaluate the various possibilities. The combination of superior adhesion and durability of our coating combined with increased resistance to many chemicals greatly reduces the chances of seeing the floor deteriorate.

Applications

- Patios

- Sidewalks

- Driveways

- Pool Decks

- Warehouses

- Hospitals

- Showrooms

- Retail Areas

- Airplane Hangers

- Commercial Kitchens

- Restaurants

- Churches

- Kennels

- Auto Dealerships

- Restrooms

- Schools

- Cold Storage

- Woods Shops

- Food Processing Plants

- Banquet Halls

- Offices

Concrete Surface Preparation

Liquid floors has the experience and the right tools to get the job done properly. We have an extensive line of preparation equipment including large 15 inch pull machines and multiple grinders from 20-32 inches pass widths. In all coatings applications, the most important step in a successful installation is the preparation of the surface. Our goal is to use this equipment to open up porosity, remove damaged or deteriorated concrete, and get rid of all chemicals or contaminants. By creating a coarse profile it allows the coating to deeply penetrate the concrete and gain maximum adhesion needed to create an eternal bond.

Damaged Concrete

Don’t be concerned if your concrete surface is pitted, cracked, and spalled. Our preparation process, repair systems and coating products will make your floor look smooth, shiny and brand new for many years to come!

Products

- Polyureas

- Epoxies

- Urethanes

- Repair Products

- Primers

- Base Coats

- Top Coats

Systems

- Chip System

- Metallic System

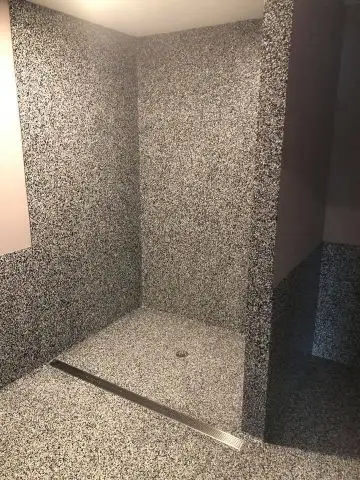

- Quartz System

- Solid Color Epoxy

- Solid Color Polyurea

- Shop Floor System

- Cove System

- Repair Systems

Urethane Cement Floors

More Info About Our Products

Polyaspartics, being as flexible as they are, expand and contract with the concrete leaving the surface strong and intact. Polyaspartics are also fully cured after 24 hrs. This does not allow the product to get harder or softer over time and with different temperatures. Epoxy/hybrid floor coatings cure to 80% in 7 days and over the course of time cure the additional 20%. During this time the product continues to get harder and more brittle causing epoxies to eventually fracture and crack causing delamination.

Polyaspartics are 4x more abrasion resistant than epoxy/hybrid floor coatings. This is due to their extreme flexibility, elongation, dense cross-linking, and mar resistance. Polyaspartics can take a tremendous amount of abuse because they are malleable and can take the physical impacts and disperse them, much like the rubber on a car tire.

Polyaspartics have 2x the adhesion over typical epoxy/hybrid floor coatings. Polyaspartics are commonly associated with spray on liners in pickup trucks. Our polyaspartics are made from the same materials, only reformulated for concrete. In a spray application, the product is cured within 17 seconds and has an eternal bond to the substrate. This same chemistry is used in our floor coating products but slowed down to an hour cure time. This gives the product time to penetrate into the concrete deeply and bond with the concrete on a molecular level. Polyaspartics are 100% UV Stable. UV Stability Is Very Important If You Want Your Finish To Look Great And Last! You Will Never See A Difference In Color With Areas That Are Exposed To UV Rays. These Areas Could Include Windows, Doors, Garage Doors, And The Portion Of The Floor That Sticks Beyond The Garage Door And Is Exposed To Light Every Day!